Pack The

Future

2023

2018 Companies And Products Awarded

Category: Ecodesign

Jokey Plastik Wipperfürth GmbH, (awarded in the EcoDesign Category)

Packaging in secondary raw materials from the post-consumer sector

It is not really an innovation for Jokey. We have produced packaging made of post-consumer secondary raw material since 1991. Unfortunately, without great success since the acceptance of packaging made of secondary raw material is not very high in the market. Even though the use of recycled material for packaging would be an important step for there cycling economy. Instead of producing the buckets completely in grey recycled material, we offer our customers the option of an individually colour scheme of the lid and the handle.

Both need to fulfil high physical requirements and offer apart from the visual perception also safety in everyday use (safety when carrying and repeated open and closing). Additionally, we decorate the packaging with ahomogenous PP-IML and give the “grey” bucketan attractive and individual visiting card at the POS. Of course, also this IML can be made with smart features like scent, watermarks and many more. In that case, the body is made of 100% post-consumer material and its “grey” appearance is nearly invisible. It goes without saying that lid sand handles can also be made of post-consumer material. Since June 2018 we advertise for the use of secondary raw material with the initiative “grey is the new green”.

Target industries: Non-food fillers such as adhesives, paints and varnishes

Nordfolien GmbH, (awarded in the EcoDesign Category)

A film that contains up to 80% recycled content.

Up to 80% recycled material content

Highly sustainable

PE based

Suitable for consumer packaging printand layout (haptic lacquer)

High mechanical strength

Odourless

No colouring

80% less virgin material resource

Less CO2 emissions

Less total energy consumption

Fulfills standards on recycling material use

No change in dimensions, thickness and weight

Fully recyclable

Emptying without residue.

Target industries: Industrial and non-food consumer packaging, e.g. fertilizers, detergents, washing powders, chemicals, building materials…

Heinz Plastics Böhm GmbH, (awarded in the EcoDesign Category)

100% recycled polypropylene cap

First fully functional closure made of 100% recycled polypropylene whose material is fully derived from the “yellow bag”. As a development partner and pioneer insustainability, the company Werner & Mertz uses bottles made from recycled material as standard in its “Frosch” brand products and closes them with the cap of Heinz Plastics Böhm. Even the green colour of the flap closure is sustainable! This closure can also be recycled, creating a closed material cycle as a contribution to protect the environment.

Target industries: Cosmetics, household products, cleaning products, leisure and horticulture

Incoplas SA, (awarded in the EcoDesign Category)

HDPE canisters with at least 50% post consumer recycled material

The “rPE bottle range” is made of HDPE resin in which at least 50% of post consumer recycled material is incorporated. While processing this resin, supplied by Total, we succeed in maintaining and even improving mechanical and technical properties of the packaging. When usually customers feared quality loss when using PCR, we can now assure them of a high and stable bottle quality. This offers a strong argument for customers to promote the use of PCR.

Target industries: Automotive Maintenance Products, etc.

Groupe Barbier, (awarded in the EcoDesign Category)

Product grouping film shrinking at lower temperatures

- reduction of the temperatures between 20 and 40°C = energy saving,

- reduction of the thickness of approximately 10μm = less plastic consuming – 18%,

- reduction of the carbon footprint with 20% of recycled material = Co2 savings – 17%,

- maintain the technical and mechanical features, visual aspect of the film,

- Slightly more expensive around 4%.

At the end, it is the combination of a technical know-how and the wish of our industrial consumers which want to reduce their carbon impact who made the success of this Low Fusion Film.

Target industries: Drinks (water, milk, beer, soup, syrup), cans (vegetables, pet food…), hygiene, freezing, compost, pellets, etc.

ALPLA Werke Alwin Lehner GmbH & Co KG, (SPECIAL AWARD)

The first recyclable bottle that uses 25% of resin collected on beaches

While other companies have utilized smaller amounts of material collected from beaches and waterways, this is the first bottle to use 25% resin reclaimed from beaches in a bottle that is also recyclable. Striving for a circular system. In close collaboration, TerraCycle, Suez, ALPLA, and Procter & Gamble have produced the world’s first recyclable bottle made from “beach plastic” waste for the shampoo brand “Head & Shoulders“. The initiative involves hundreds of NGOs and thousands of volunteers collecting and recycling plastic found on beaches. Plastic coming from the marine environment is notoriously difficult to re-use due to environmental degradation by elements such as sun (UV radiation) and salt water. Dirt and biological films attach to the plastic in the environment and must be adequately cleaned off the resin during processing. A significant level of development was required to prepare the collected beach plastic for bottle manufacturing. The packaging offers the same product protection and consumer safety as regular Head & Shoulders bottles in the market; no compromises were made. The product was launched in France in June 2017. The launch is intended to not only help clean up plastic on beaches but also drive awareness and inspire consumers to play their part in recycling.

Target industries: Body and beauty Care

RPC Bramlage, (awarded in the product protection category)

Packaging with recycled material that enables the distribution of preservative-free cosmetic cream

RPC Bramlage has developed in partnership with Pierre Fabre Dermo Cosmetique a packaging which allows to dispense cosmetic cream without preservative and also to be sustainable by integrating circular economy with PCR. The innovation resides in the pump which integrates a closing valve in the actuator to shut the opening. This valve will open when we actuate the pump and the product will be dispensed. When the actuator moves up, the valve will shut the opening. The performance of the one-way valve has been validated by micro bio tests during several weeks and no bacteria contaminated the inside of the pump or the bottle. The pump is mainly made of polyolefins (PP and LDPE). It is 100% plastic; and it is 100% recyclable. The complete system, pump + bottle, have been developed to dispense very viscous cosmetic cream. This will reduce product losses in the bottle. The Airless bottle allows to integrate PCR material in the external layer of the bottle and between this PCR layer and the formula we have a barrier layer which protects the formula against potential migration from the PCR. This packaging innovates a lot because it combines safe cosmetic formula with no preservative and sustainability with potential PCR integration for circular economy.

Target industries: Body and beauty care

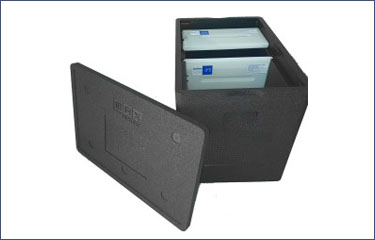

OHLRO Hartschaum GmbH, (awarded in the product protection category)

A transport box with which the temperature can be kept between 2° and 8° C for at least 250 hour

Our O-BOX H250 provides a new option for the transport of temperature-sensitive goods of any kind, such as pharmaceutical products, food and chemical products. By skilfully combining different materials, we were able to develop a transport box with which the temperature can be maintained in a range of 2° to 8° C for at least 250 hours. The box consists of foamable plastics with a positive thermal conductivity coefficient. Furthermore, all external walls have hollow chambers in which vacuum insulating panels(VIP) are located. This prevents heat exchange with the environment. In addition, latent heat storage units (PCM) ensure that the temperature inside the box remains stable for a long time. The special interior design enabled our prototype to maintain the temperature between 2° and 8° C for over 250 hours according to the ISTA summerprofile during a check. Currently, the box has a usable internal volume of approx. 30 litres, where in additional volume is possible if required. Another advantage is that the use of foamable plastic significantly reduces the weight of the packaging compared to existing solutions. The VIPs are protected in such a way that they are not immediately destroyed if the box is handled improperly.

Target industries: Food, pharmaceuticals, biotechnology, chemistry, medicine

RPC Bender GmbH, (awarded in the social benefit category)

Sports cap for bottles

SecureFlip – A new innovative consumer friendly flip-top Sportscap closure for the PCO1881 bottleneck finish. The new Secure Flip 1881 Sports Closure features intuitive one-hand opening, together with a modern ergonomic and sustainable design. The cap opens by one-hand to a full and stable 180°, providing easy and comfortable access for the consumer to drink from the closure spout by doing sports or simply “on-the-go”. The sustainable tamper-evident band within the closure breaks on first opening. The SecureFlip tamper-evident band ring is retained highly visible within the closure, which is a main advantage vs. other sport closure concepts with a detachable tab, which will be thrown away by the consumer and will pollute the environment. A second tamper-evident band on the base of the closure stays on the bottle after unscrewing and so it can be recycled as other tamper-evident bands of standard beverage closures on non-returnable plastic bottles. Secure Flip is currently available in 1881 neck finish from RPC Bender Frankenthal and in 29.25from other RPC facilities. More neck finishes are in development. The new SecureFlip can be fully individualised, to strengthen customer products and brands with unique colours for each of the 3 components of the closure.

Target industries: Food, in particular beverage industry

BETAPACK, (awarded in the social benefit category)

Attached bottle cap

The SNAP CLIC PELICAN cap is a new cap attached to the bottle: it is an ECORESPONSABLE cap (less plastic on the cap and less PET on the neck finish of the bottle).

practical: The hood can tilt to more than 180ºand when the reclosure is clipped and easily disengages on the front

hygienic: it is not likely to fall to the ground, or to get lost in nature

functional: it is easier to open than a screw cap and the hood tilts at the back (click tilt) to clear the neck of the bottle environmentally friendly: the cap is systematically recycled with the bottle (recyclability of the packaging 100%)..

Target industries: Food, in particular beverage industry

BERNHARDT Packaging & Process, (awarded in the social benefit category)

A bag to make room in hospitals

BERNHARDT’s STERI-LIQUID POUCH is the first 5L pouch designed for liquids that require sterilisation. Easy to use and empty with its top and bottom handles, it can withstand a 1.5 h autoclave cycle, including 30 minutes at 121.4°C. Made of PA and medical-grade PP, it aims at replacing jerrycans and as such reducing by a factor of 10 the volume of waste that hospitals have to manage. The applications are wide and range from sterile water to dialysis solutions. Specific attention was given to the pouch’s mechanical resistance (it passes drop tests from a height of 1 meter). Less space for empty jerrycans means more space for things that matter and most of all for patients. We estimate the net annual gain for the largest hospitals at 135 cubic meters which is equivalent to saving 10 garbage truck rotations per hospital. Across France, Germany and the UK, this is comparable to saving the total annual garbage collection of a city of 100,000 inhabitants. The STERI-LIQUID POUCH offers a goodwaste-to-energy potential as its components are studied for clean incineration without residues. Its foil cannot be considered recyclable yet as the technology for separating plastics layers is not advanced enough.

Target industry: Healthcare

OLIVO et KNAUF INDUSTRIES, (awarded in the save food category)

An isothermal transport solution

The BOX MAX 64 is an isothermal solution co-developed by OLIVO and KNAUF INDUSTRIES. This packaging meets the needs of temperature-controlled transport, especially for food and for the last mile deliveries. Able to maintain fresh or frozen products thanks to its eutectic solutions at -3 ° C or -21 ° C, the BOX MAX 64 this time meets the challenge of bi-temperature. Thanks to a modular EPP partition, a single BOX MAX 64 can simultaneously transport fresh products at + 2 ° C and frozen products at -18 ° C. The fresh products are stored in the fresh compartment in the same time as the frozen ones in the frozen compartment of the BOX MAX 64. Its dimensions (¼ pallet Europe), its lightness(2kg empty) and its customization options make it a simple tool, easy to integrate into a logistics scheme. The BOX MAX 64, easily washable and reusable for several years, is also 100% recyclable. It is made of EPP, including 15% recycled material. It enables city centre deliveries in light, low noise and low pollution vehicles. It is part of a development approach of the circular economy, pillar of sustainable development.

Target industry: Food